The RUD Tecdos MSB maintenance station is the all-in-one solution for improved tool handling, as it enables simple and optimised maintenance of tools and moulds. The innovative maintenance station is therefore ideal for use in injection and die casting technology as well as in tool and mould making.

Gap in the market identified

"This is completely new on the market: just one device that can be used to perform all the important steps in handling moulds and tools weighing up to 2 tonnes. From opening and turning to maintenance and testing. Similar solutions have only been available in weight classes of several tonnes," explains Anne Kühling, Product Manager in the Conveying and Drive Technology division at RUD Ketten Rieger & Dietz GmbH u. Co. KG. The specialist for mould handling solutions recognised this gap in the market and developed the maintenance station, which is a useful addition to the product portfolio, especially for lighter and more compact tools and moulds.

All-in-one tool handling

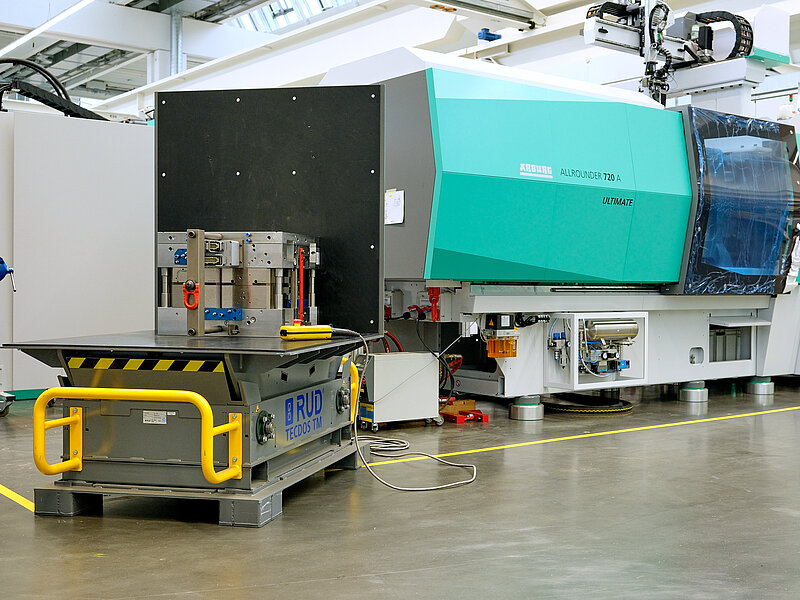

The RUD Tecdos MSB maintenance station is based on the RUD Tecdos TMB industrial workbench with integrated turntable (120 cm x 80 cm). It ensures safe and ergonomic turning of tools weighing up to 2 tonnes – simply by using a cordless screwdriver. New: with an additional opening function and test device, it becomes an all-in-one maintenance station. T-slot rails are attached to one side of the tool turner to securely fix tool halves in place.

Particularly cool: thanks to a compressed air-supported plate, moulds and tools weighing up to 2 tonnes can be moved easily and safely at the touch of a button and processed directly on the maintenance station. "Basically, the air cushion makes it easier to open the tools and moulds. But the optional hydraulic unit for ejector tests also allows a tool assembly with back pressure pins to be opened," explains Jochen Schwegler, Technical Application Engineer at Nonnenmann GmbH.

Simplified and optimised processes

As a compact unit, RUD Tecdos MSB fits into any workshop and simplifies processes and handling. The maintenance station eliminates time-consuming intermediate steps and standardises the workflow instead: opening, turning, cleaning, maintaining and testing the tools and moulds are all carried out centrally on one device.

Tests and quality controls

The maintenance station not only optimises tool handling processes, but also increases tool quality and process reliability in general. ‘Our experience and feedback from the market show that, due to time constraints, many tools are not checked but are instead inserted directly into the machine. If malfunctions or problems then occur, for example because the temperature control channels are blocked or leaking, the tool has to be removed from the injection moulding machine and repaired. This costs time and money,’ emphasises Anne Kühling.

To avoid unpleasant surprises later in the injection moulding machine, tools and moulds can be checked quickly and easily directly on the RUD Tecdos MSB maintenance station, for example by means of ejector or temperature control leak tests.

Increased occupational safety and ergonomics

The maintenance station is also ergonomic and safe to use, as it enables work to be carried out in full compliance with DGUV regulations. ‘Anyone who drags or pulls loads across the hall floor with a crane is not only working dangerously, but also contravening current standards, as this is expressly prohibited by Section 37 of the accident prevention regulations for cranes issued by the German employers' liability insurance associations,’ says Kühling. With RUD Tecdos MSB, cranes, ropes and crowbars can take a break.

Wide product portfolio

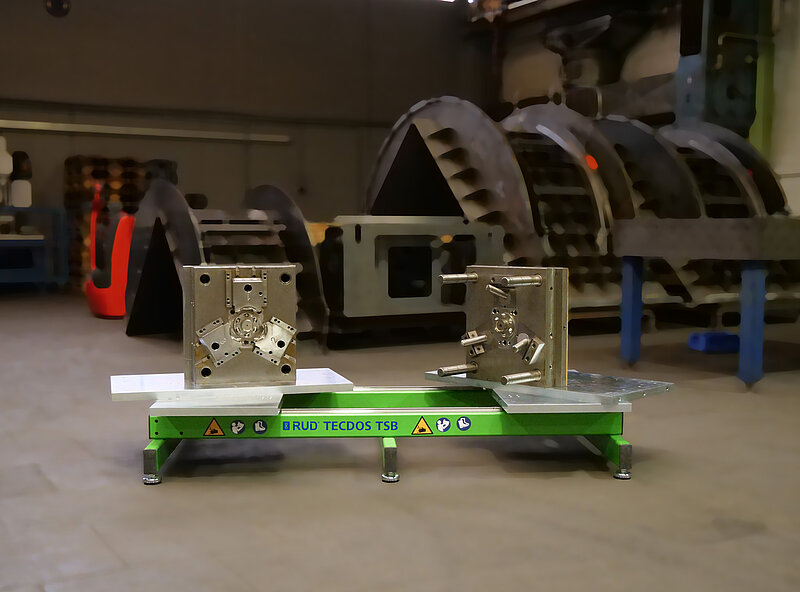

The RUD Tecdos MSB maintenance station is already the fifth innovation in the field of mould handling within just a few years. ‘This shows how great the need for process optimisation and occupational safety is, especially in the injection moulding industry,’ emphasises Kühling. The RUD Tecdos TM turntable and the RUD Tecdos TMB industrial workbench turn tools and moulds gently and safely. Separation is handled by the RUD Tecdos TS electric tool opener and the RUD Tecdos TSB manual tool opener.