New tool opener for tools weighing up to 2.5 tonnes. RUD is thus further expanding its Mould Handling Solutions division.

Say goodbye to crowbars and hammers and hello to a new way of manual tool handling! RUD TECDOS TSB (short for Tool Separator Bench) is the latest innovation from RUD Ketten Rieger & Dietz GmbH & Co. KG, based in Aalen, Baden-Württemberg. With the RUD TECDOS TSB, opening and closing tools weighing up to 2.5 tonnes is now particularly quick and easy, and can be done by hand. That's right, without any additional gripping tools. Great for the workflow in the injection moulding industry: the opened tool halves can be cleaned and maintained directly on the tool opener thanks to 360-degree rotation. RUD TECDOS TSB is already the fourth RUD innovation for efficient tool handling. The specialist is thus further expanding its RUD Mould Handling Solutions division and once again establishing itself as a solution provider for end-to-end tool handling. Further information: www.moldhandling.rud.com

"Moulds and tools weighing up to 2.5 tonnes present many users in the injection moulding industry with a dilemma: they are actually too heavy to be opened and closed manually, but the use of larger auxiliary equipment is also inefficient. With the RUD TECDOS TSB, we offer an adequate solution for efficient and safe opening and closing," explains Anne Kühling, Product Manager in the Conveying & Drive Technology division at RUD Ketten Rieger & Dietz GmbH u. Co. KG.

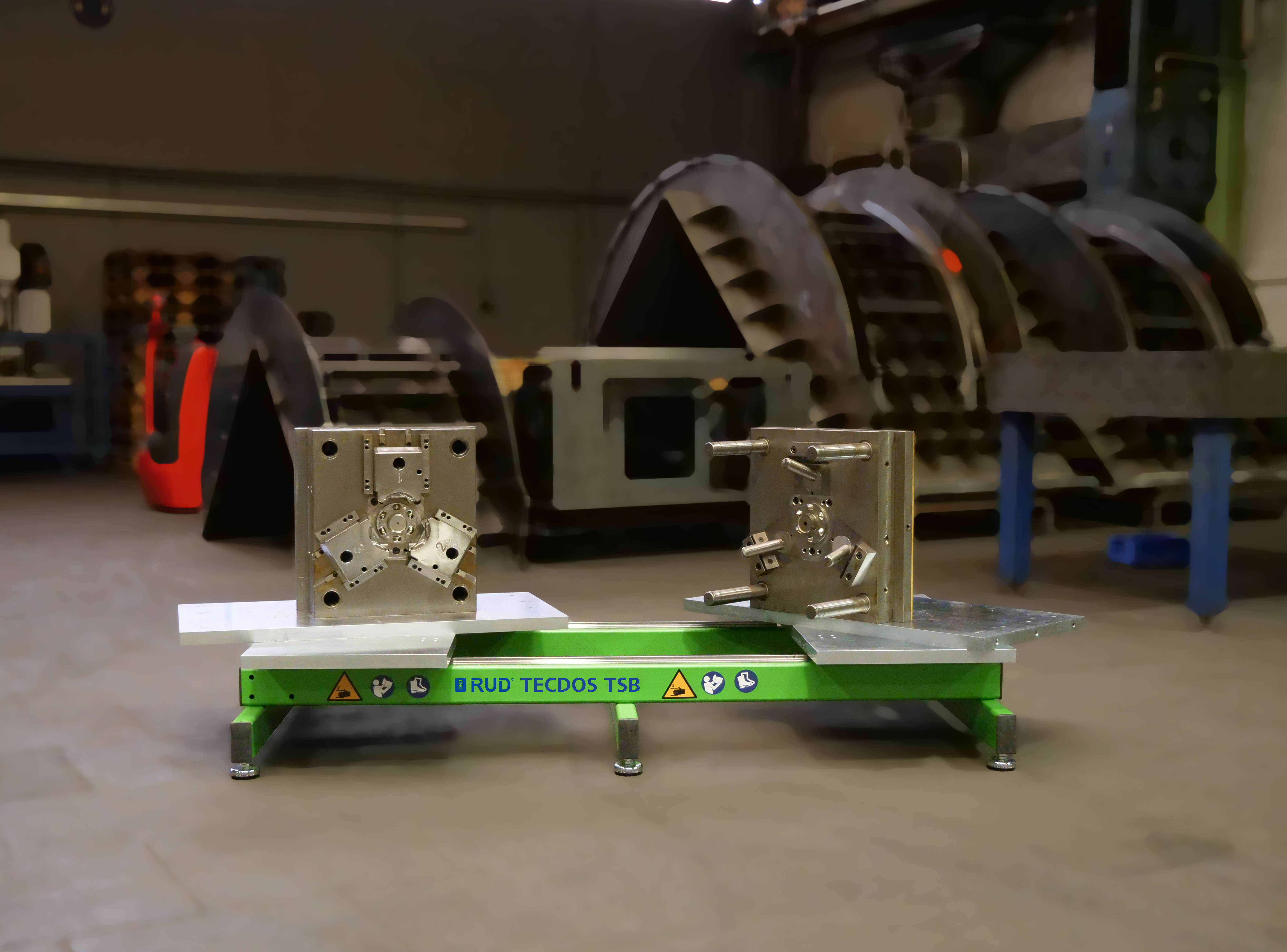

RUD TECDOS TSB for tools up to 2.5 tonnes.

The new RUD TECDOS TSB tool opener is suitable for tools and moulds weighing up to 2.5 tonnes. It enables manual and controlled opening and closing without the use of gripping tools or additional electrical, pneumatic or hydraulic energy. The two movable mounting plates alone allow light and medium-weight moulds to be opened and closed easily, quickly, safely and ergonomically by hand. There is no need for time-consuming dismantling of hoses, connections and other components.

The RUD TECDOS TSB is available in two versions with different sized mounting plates measuring 60 cm x 40 cm or 80 cm x 40 cm. Thanks to the low working surface of 31 cm, working with the new tool opener is particularly ergonomic.

Optimised workflow and maximum efficiency.

The movable mounting plates of the RUD TECDOS TSB have a special feature: they can not only be moved to open and close the moulds and tools, but can also be rotated through 360 degrees. This allows the opened tool halves to be rotated vertically around their own axis – for easy inspection, cleaning and maintenance directly on the work surface of the tool opener. The mounting plates can be fixed in place for tool machining using a locking mechanism.

RUD TECDOS TSB can be operated easily, safely and quickly by just one person. ‘With our latest innovation, we are not only reducing handling times, but also the time employees spend on the job. This results in a doubly optimised tool handling process,’ emphasises Kühling. Thanks to its low weight and compact dimensions, the new RUD TECDOS TSB tool opener can be used flexibly throughout the entire plant.

Mould Handling Solutions from RUD

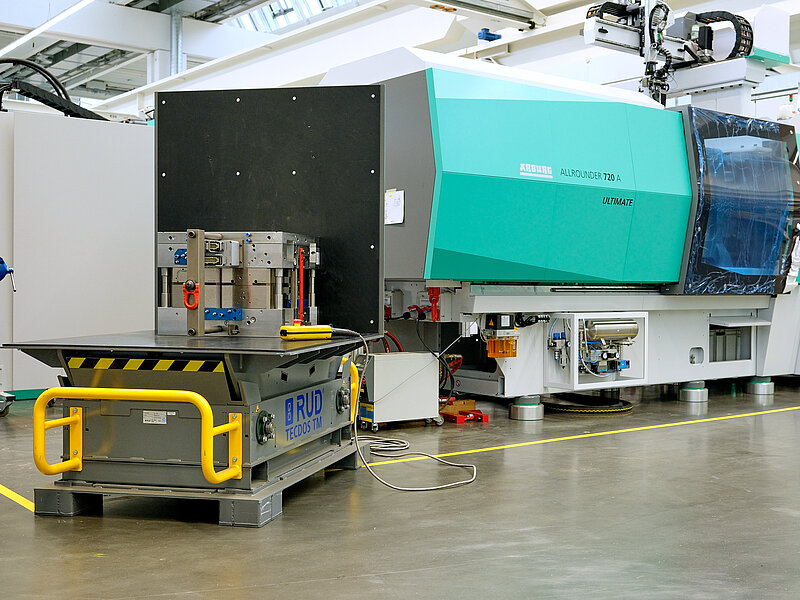

RUD offers the right solution for every step in tool handling. The RUD TECDOS TM tool turner is ideal for the maintenance and repair of moulds and tools weighing up to 64 tonnes. It turns and rotates tools and moulds weighing several tonnes – in less than a minute. The RUD TECDOS TS tool opener opens and closes injection moulding, punching and forming tools weighing up to 10 tonnes in just a few seconds. The RUD TECDOS TS requires a maximum of five minutes for the entire opening process, revolutionising production, maintenance and repair workflows.

Like the new RUD TECDOS TSB, the RUD TECDOS TMB industrial workbench is designed for tools and moulds weighing up to 2.5 tonnes. The 2-in-1 combination of industrial workbench and turning table not only allows light and medium-weight injection moulds to be turned efficiently and safely, but also maintained directly on site. ‘Together with our RUD TECDOS TMB industrial workbench, our new RUD TECDOS TSB tool opener offers the ideal combination of tool turner and tool opener,’ says Kühling.

Process optimisation and occupational safety: demand is high.

When handling moulds and tools weighing several tonnes, but also lighter ones, there is much to be gained from efficient and safe working, especially in maintenance and repair. Not only does it save time and money, it also protects the infrastructure in the plants and contributes to the occupational safety of the employees.

RUD has seen first-hand in recent years just how great the demand for process optimisation and occupational safety is, especially in the injection moulding industry. "Ten years ago, we developed our first innovation, the RUD TECDOS TM tool turner. Our other solutions followed within the last three years. For all four developments – RUD TECDOS TM, RUD TECDOS TS, RUD TECDOS TMB and, most recently, RUD TECDOS TSB – the impetus came directly from the market,‘ explains Kühling. ’It is therefore only logical for us to focus even more strongly on our RUD Mould Handling Solutions division and to expand it further."

Author: Sabrina Deininger