RUD TECDOS MSB

The revolutionary solution for tool and mould making

In the injection moulding industry and in mould making, efficient maintenance and testing of tools is crucial. Without defined test processes and the right equipment, tools are often not optimally maintained, which can lead to production downtime and high costs. This is where the comes into play - the maintenance station that increases your efficiency and simplifies production planning.

RUD TECDOS MSB maintenance station

Tools in injection moulding plants and mould making must be regularly maintained and tested. This is crucial to avoid production downtimes and ensure predictable manufacturing. However, defined test processes and the right equipment are often lacking, leading to improvised repairs and increased costs. The RUD TECDOS MSB offers the perfect solution here by combining test and handling functions, thereby optimising the entire process.

Interested? Then give us a call on

+49 7361 504-1457 or send us an email.

Hydraulic unit

The hydraulic unit of the RUD TECDOS MSB provides the necessary power for precise movements and ejector tests. It ensures reliable and controlled control of the hydraulic cylinders for efficient testing and safe maintenance of tools.

Turning frame

The reversible frame of the RUD TECDOS MSB enables controlled and safe turning of tools during maintenance and testing. This allows inspections, leak tests and maintenance work to be carried out efficiently and ergonomically – without additional repositioning of the tool.

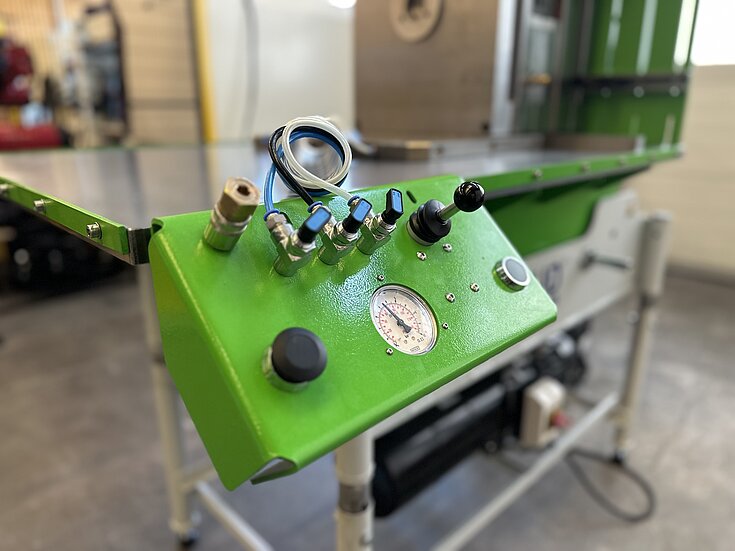

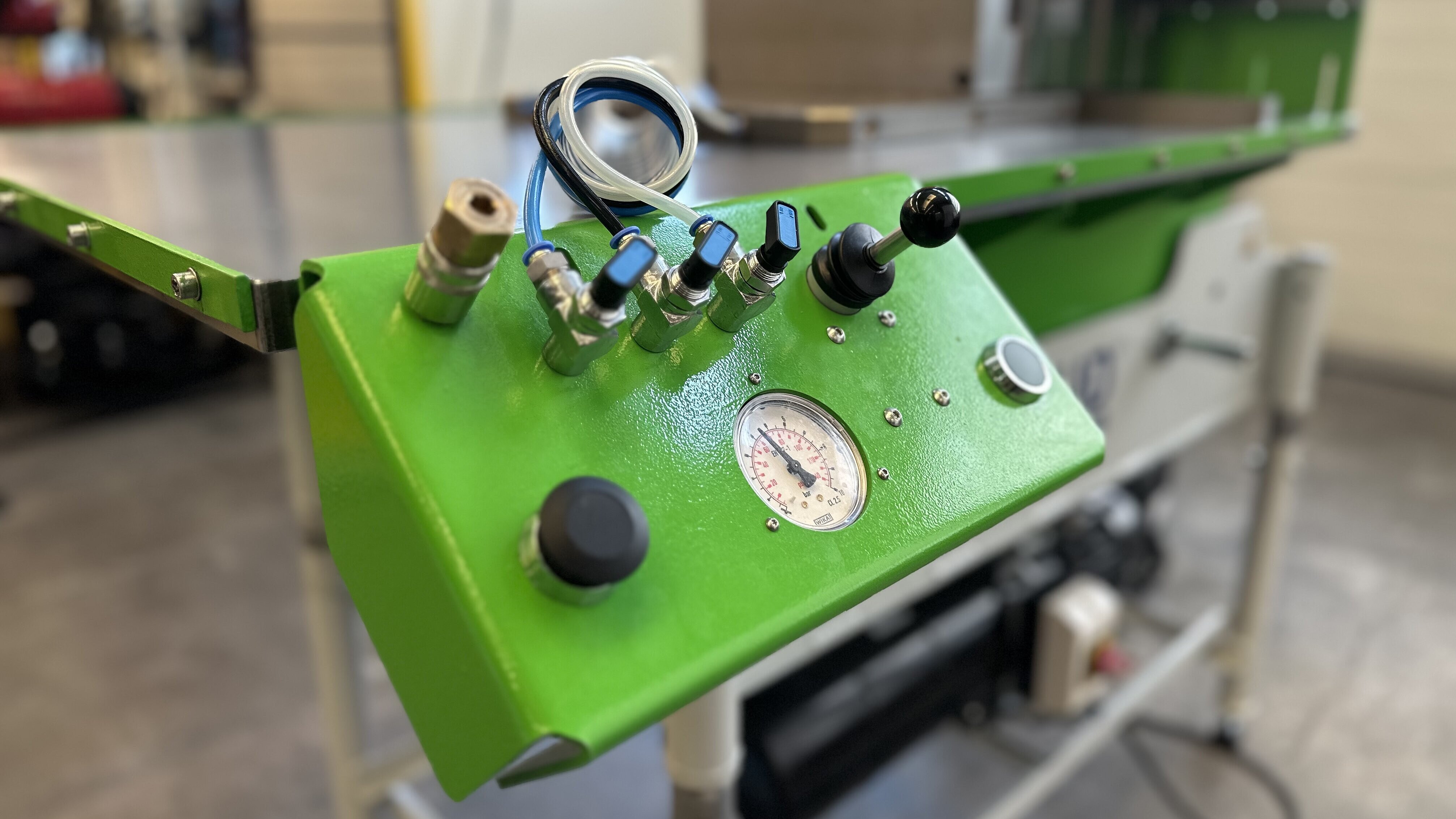

Control panel

The control panel of the RUD TECDOS MSB enables convenient and precise control of all test and maintenance functions.

Height-adjustable T-slot rails

The height-adjustable T-slot rails of the RUD TECDOS MSB ensure individual adaptation to different tool sizes. They enable secure fixing during testing and maintenance, thus contributing to a stable and efficient work process.

Hydraulic cylinder / Ejector test

The hydraulic cylinder of the RUD TECDOS MSB enables a realistic ejector test directly on the test bench. This allows ejector movements to be precisely simulated and tested to ensure that the tool functions flawlessly – for maximum process reliability and efficiency.

Air-bearing plate

The air-bearing plate of the RUD TECDOS MSB reduces friction to a minimum and enables precise, energy-saving movement of tools. This means that even heavy moulds can be positioned easily and safely without damage or excessive effort.

Your advantages at a glance

Reduce production risks such as downtime and rejects in in-house and contract manufacturing with comprehensive tests and centralised processes. Save time and resources, increase productivity despite a shortage of skilled labour and ensure maximum safety through clear labelling.

- The risk of failures and rejects is reduced in both in-house and contract manufacturing.

- Comprehensive testing prior to production prevents unexpected production downtime.

- Minimal training time and centralised maintenance enable immediate productivity.

- Centralisation of tools and materials reduces travel and waiting times, as all maintenance work is carried out centrally in one place.

- Labelling of safety-relevant points ensures safe operation.

| Type | WORKING TABLE IN MM | CLAMPING PLATE WITH T-SLOTS IN MM | WORKING HEIGHT ADJUSTABLE IN MM | AIR-BEARING SUPPORT PLATE IN KG | LOAD CAPACITY IN KG | Size of the air-borneMold Half in mm | Max. Height of the air-borne Mold Half in mm | Max. weight of the air-borne Mold Half | Max. weight of the Mold in total | OWN WEIGHT APPROX. IN KG |

|---|---|---|---|---|---|---|---|---|---|---|

| MSB without hydraulics | 1200 x 800 | 800 x 800 | 880 x 1100 | 496 x 396 | 2.000 | 600 x 500 | 600 | 1.000 kg | 2.000 kg | 500 |

| MSB with hydraulics | 1200 x 800 | 800 x 800 | 880 x 1100 | 496 x 396 | 2.000 | 600 x 500 | 600 | 1.000 kg | 2.000 kg | 550 |

Turning table RUD TECDOS TMB: Revolutionise your workshop

The RUD TECDOS TMB industrial workbench with integrated turning table will revolutionise your workshop. With this turning table, you can work efficiently, safely and accurately and take your workshop to a new level. Turns, rotates and tilts tools weighing up to 2.5 tonnes and enables tools to be machined on the industrial workbench.