TURNING DEVICE RUD TECDOS TM.

Flexibly turn, rotate and tilt injection moulding tools, punching tools and forming tools weighing up to 64 tons.

The RUD TECDOS TM turning device (also known as a turning traverse, turning table or tool turner) turns, rotates or tilts tools in seconds at the touch of a button. The compact turning device does not need to be anchored to the floor. This makes it easy to transport the tool turner using a forklift truck, and turning injection molds, punching tools and forming tools has never been so safe and efficient. The amortization period for the tool turner is less than one year. The RUD TECDOS TM turning device is therefore a cost-effective mechanical engineering solution to prevent damage and hazards during tool handling.

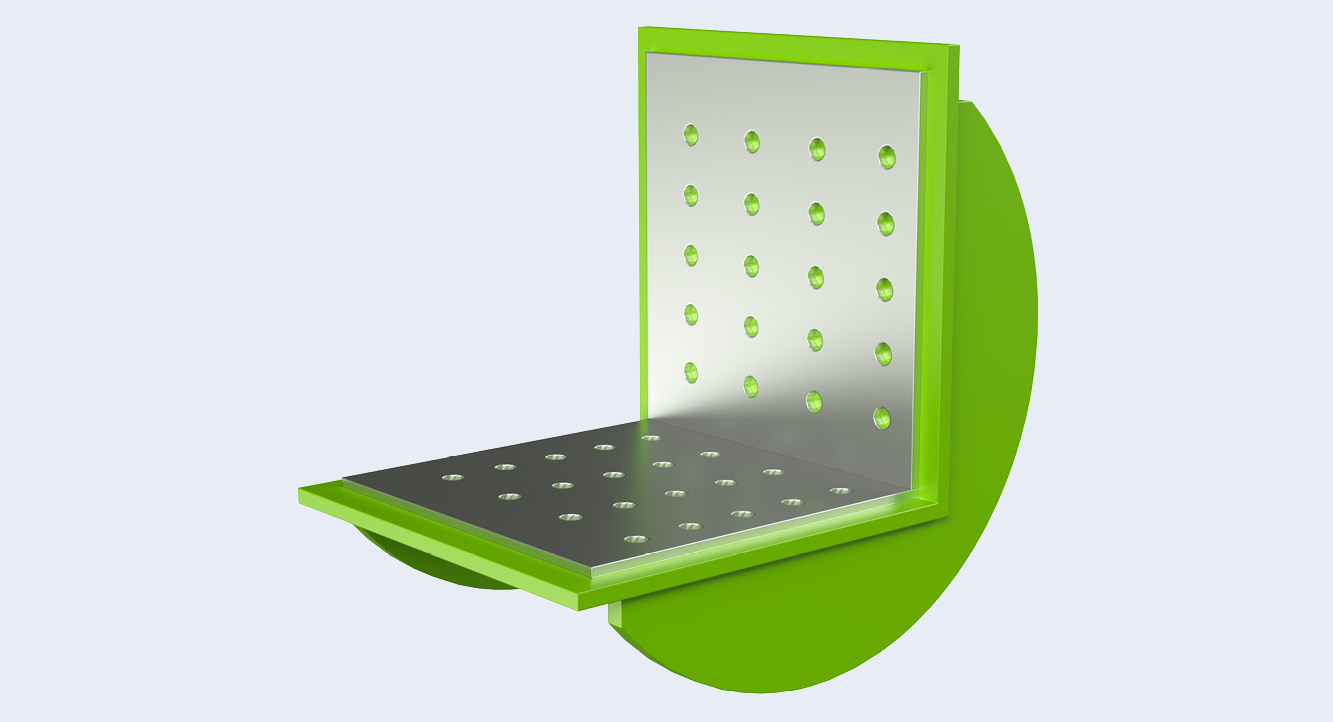

Construction and components of mold flipper RUD TECDOS TM.

The mold flipper RUD TECDOS TM is controlled remotely and can turn, rotate, or tilt injection molds weighing up to 140,000 pounds in a matter of seconds.

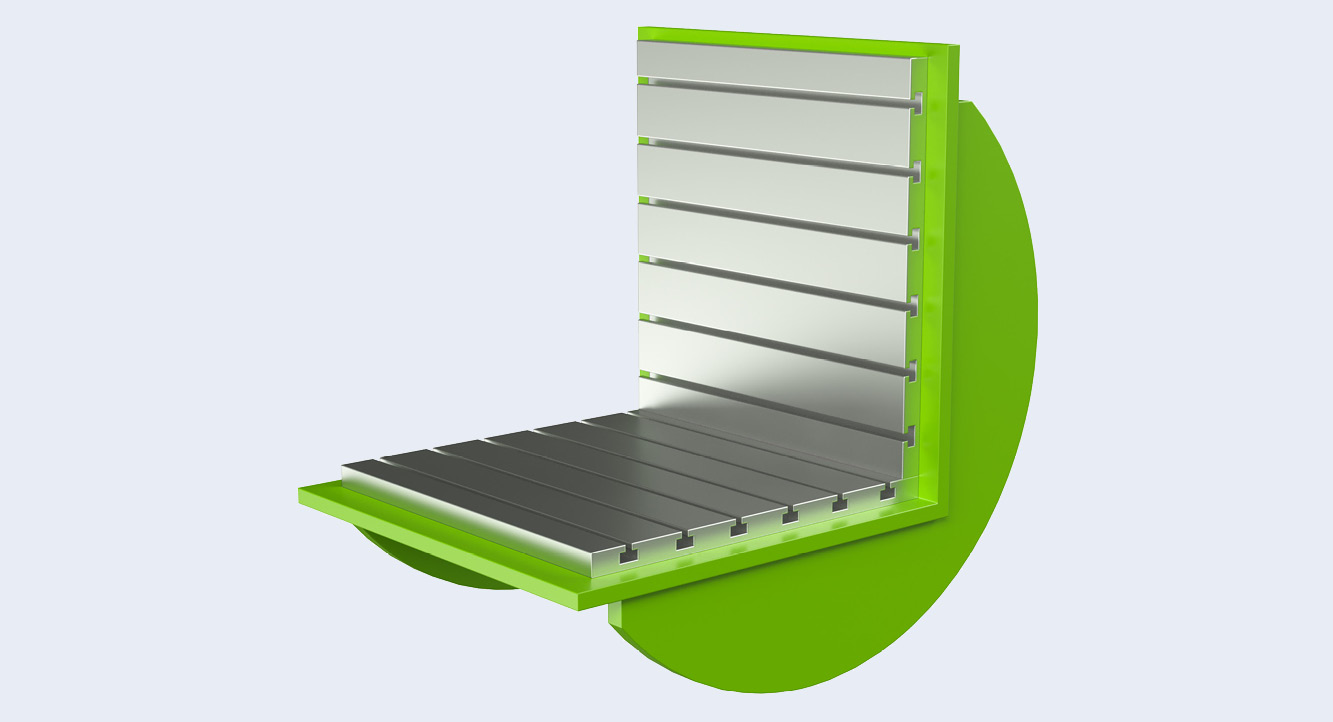

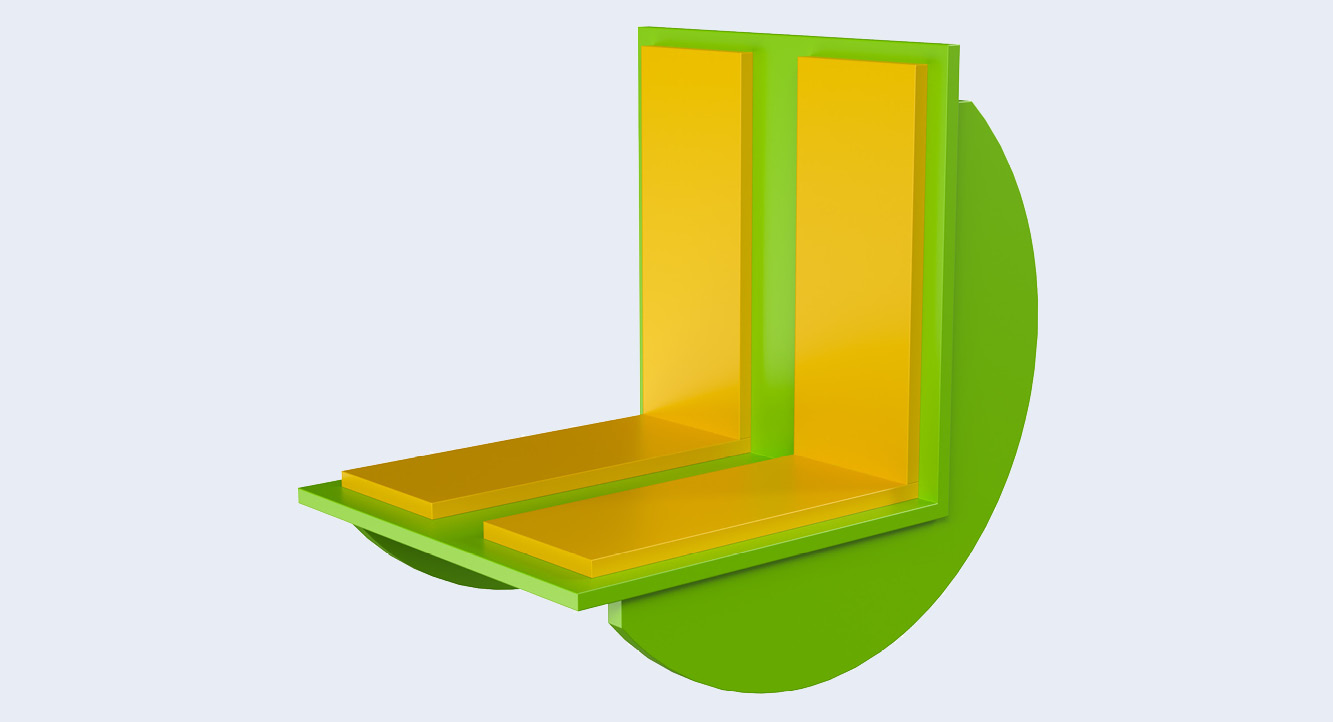

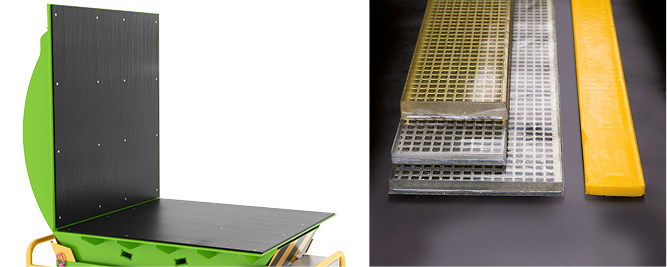

RUD TECDOS TM platforms.

On request, you can get a bespoke platform for your RUD TECDOS TM. Choose a platform that is specifically tailored to your requirements or contact us with your enquiry.

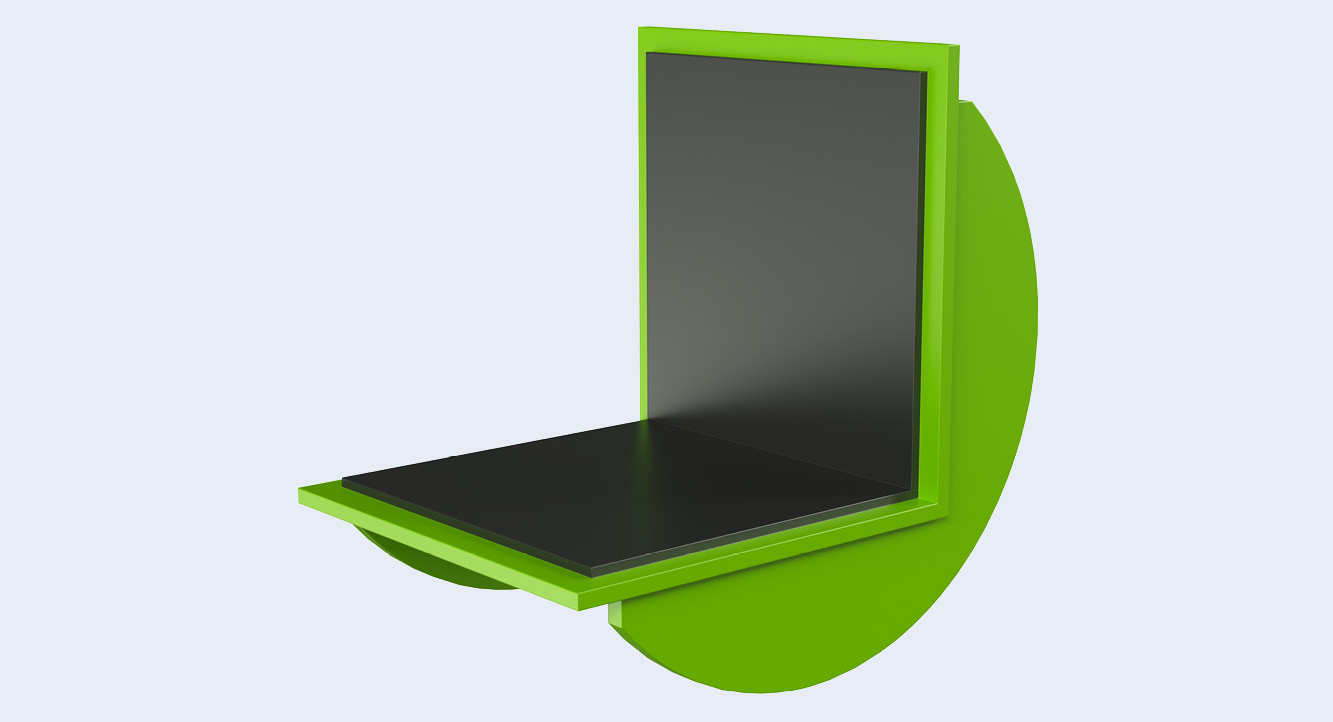

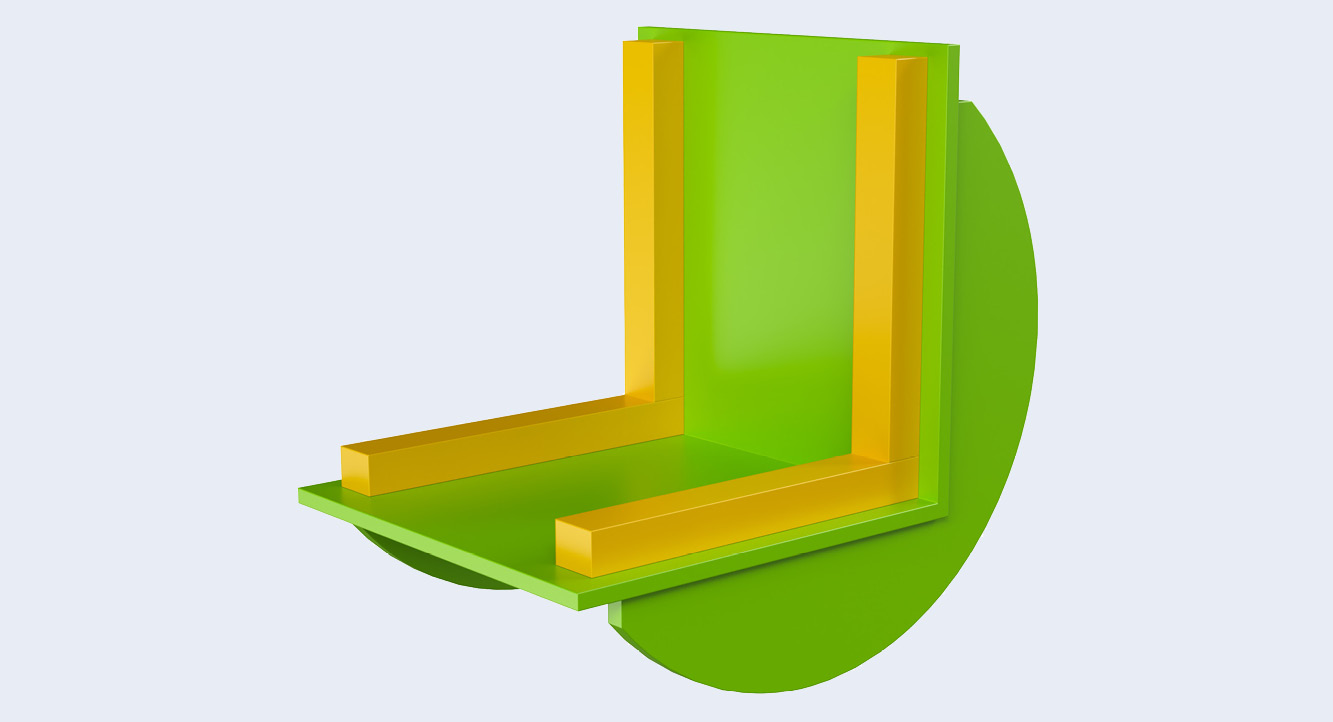

RUD TECDOS TM contact protection (optional).

- Protects operators from reaching into the danger zone (crushing hazard)

- Protective yellow/black plate

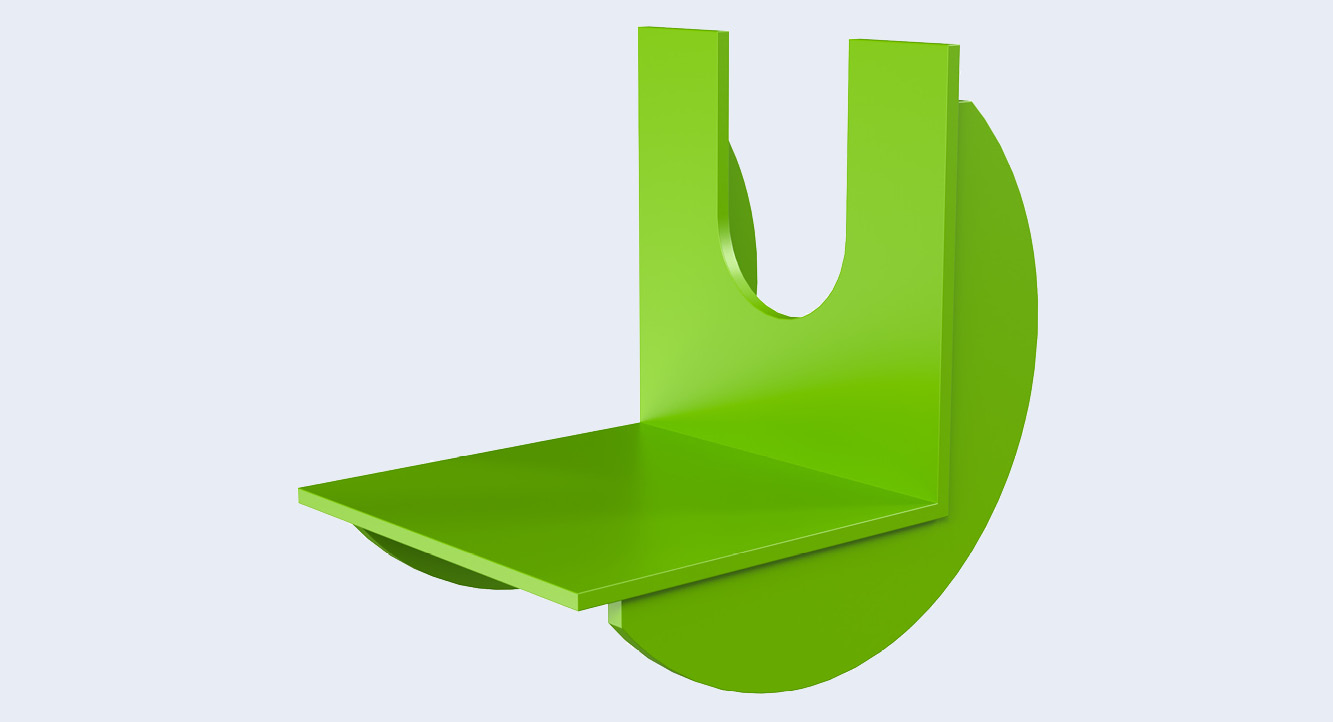

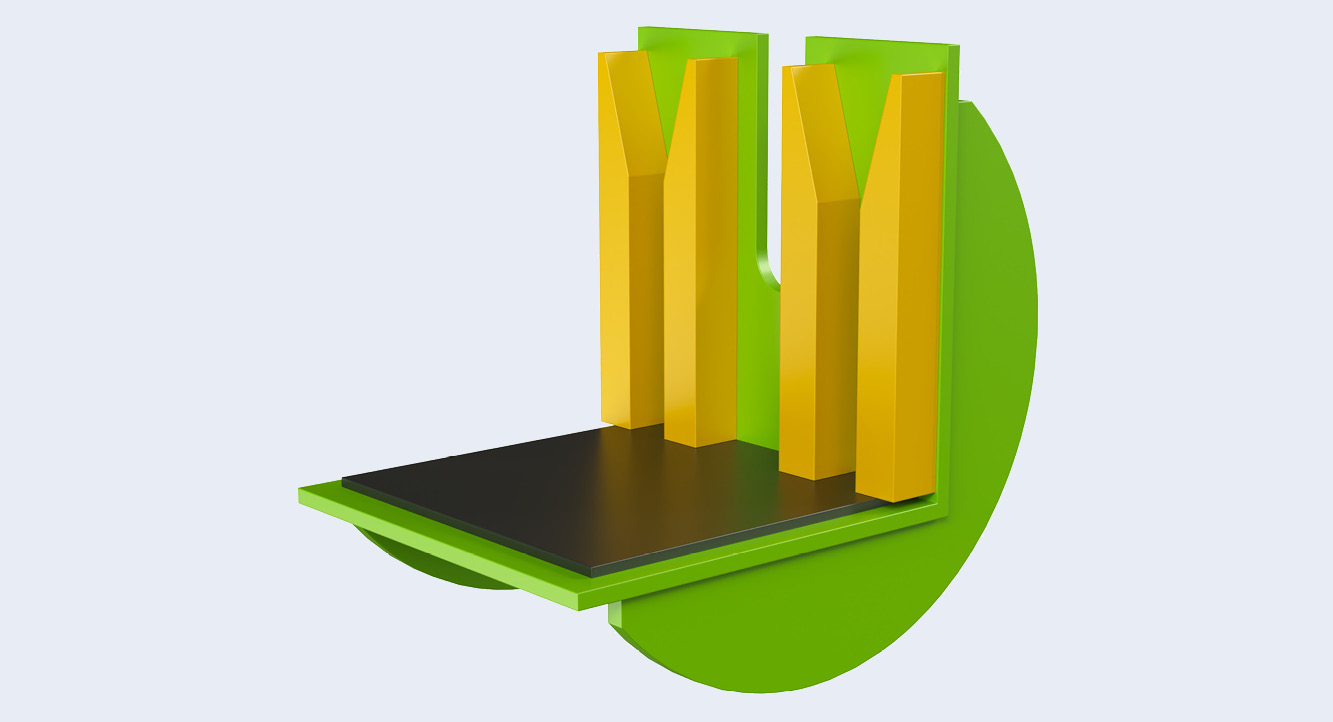

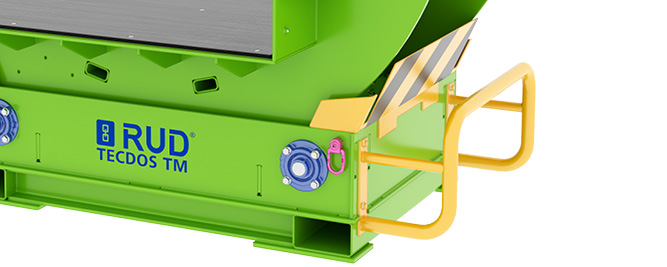

RUD TECDOS TM guard bracket (optional).

Hoop design provides distance protection:

- For the front zone

- For the rear zone

- RUD TECDOS TM tool-protecting turning device for the injection molding industry

- Ensures the safety of the operator and the molds

- Ergonomic mold handling

- Operation of the mold turner by just one employee

- Time and cost savings when turning injection molds and dies

- Robust, flexible and maintenance-friendly turning device - designed to meet your needs

- Option to extend the warranty

| Type | Table surface in inch | Table top height in inch | Load capacity in lbs | Weight in lbs |

|---|---|---|---|---|

| TM 08/10-5 | 31.5 x 39.4 | 21.3 | 11,000 | 1,323 |

| TM 08/13-10 | 31.5 x 51.2 | 23.4 | 22,000 | 2,315 |

| TM 13/13-10 | 51.2 x 51.2 | 23.4 | 22,000 | 2,315 |

| TM 15/18-16 | 59.1 x 70.9 | 34.8 | 35,200 | 8,159 |

| TM 20/20-20 | 78.7 x 78.7 | 34.8 | 44,100 | 8,820 |

| TM 20/23-25 | 78.7 x 90.5 | 45.9 | 55,100 | 17,640 |

| TM 25/25-32 | 98.4 x 98.4 | 45.9 | 70,500 | 17,640 |

| TM 25/25-40 | 98.4 x 98.4 | 45.9 | 88,200 | 17,640 |

| TM 25/35-64 | 98.4 x 137.8 | 81.7 | 64,000 | 37,485 |