The proven RUD Tecdos TM tool turner is now also available in a “small version.”

"Manufacturers of plastic parts for the automotive industry, users in medical technology, packaging manufacturers, and anyone who uses injection molding tools can rejoice: We now also have a solution for the safe, efficient, and ergonomic handling of molds and tools weighing up to five tons,“ explains Anne Kühling, Product Manager in the Conveying & Drive Technology division at RUD Ketten Rieger & Dietz GmbH u. Co. KG. ”With the new weight class of the RUD Tecdos TM, we have perfectly complemented and consistently expanded our mold handling portfolio," Kühling continues.

Five tons turned efficiently and safely.

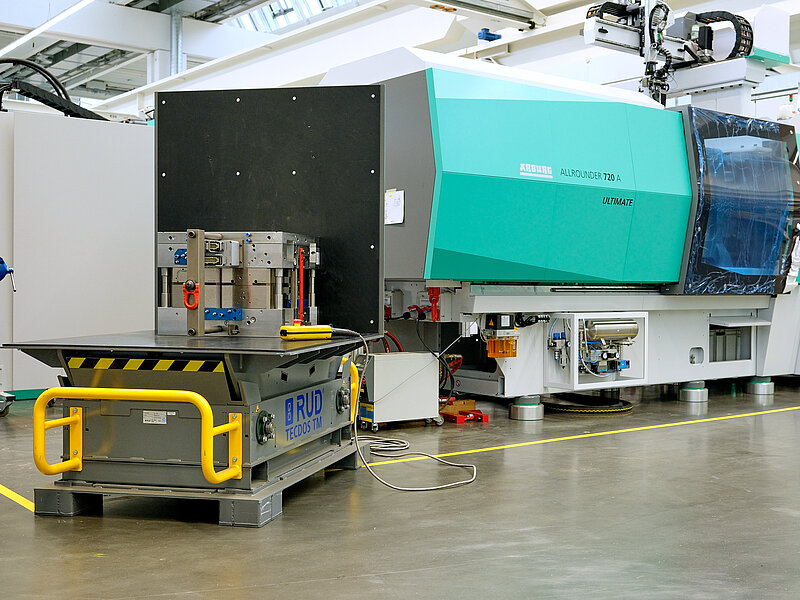

The five-ton version of the RUD TECDOS TM can accommodate tools and molds weighing up to five tons on its 80 x 100 cm table surface. The tool turner is predestined for use in the injection molding industry. However, the five-ton tool turner also optimizes processes in tool and mold making, in punching, bending, and forming technology, in the automotive sector, and in the electronics and packaging industries.

With its compact dimensions of approx. 140 x 80 cm x 100 cm, the RUD TECDOS TM in its five-ton version is particularly space-saving and flexible in operation and can be moved using a pallet truck, forklift or crane.

Turning in 30 seconds.

Compared to tool handling with a crane, turning with the RUD TECDOS TM 08/10-5 is at least twice as fast and takes just half a minute. Plugs or cooling hoses, which often have to be removed for safety reasons during crane maintenance, can simply remain in place during maintenance with the innovative turning table from RUD.

Ergonomics and occupational safety in focus.

The RUD TECDOS TM 08/10-5 revolutionizes the maintenance and repair of molds and tools, enabling absolutely safe working in compliance with BGV regulations. Anyone who drags or pulls loads across the hall floor with a crane is not only working in a fire-hazardous manner, but also in violation of current standards, §37 of the accident prevention regulations for cranes issued by the professional associations.

Demand from the market.

“The impetus for the development of our Mold Handling Solutions came directly from the market. This was also the case with our expansion, the five-ton version of the RUD TECDOS TM. This shows that there is still a great need and demand for efficient, safe, and ergonomic handling solutions for molds and tools in different weight classes,” says Kühling.

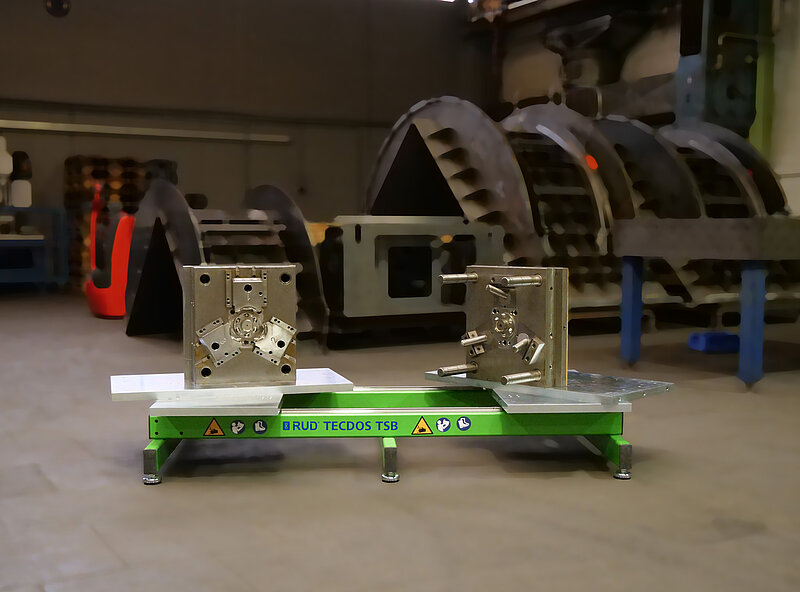

RUD launched its first innovation in the field of mold handling more than ten years ago: the RUD TECDOS TM tool turner for tools and molds weighing up to 64 tons. Further developments were gradually added. The Mold Handling Solutions division now comprises a total of four products for turning, opening, and closing tools: the classic RUD TECDOS TM tool turner, the RUD TECDOS TS tool opener, and their bench versions for tools up to 2.5 tons, the RUD TECDOS TMB and TSB.

Author: Sabrina Deininger