The new tool opener from RUD not only optimizes processes, but also improves occupational safety in the workplace.

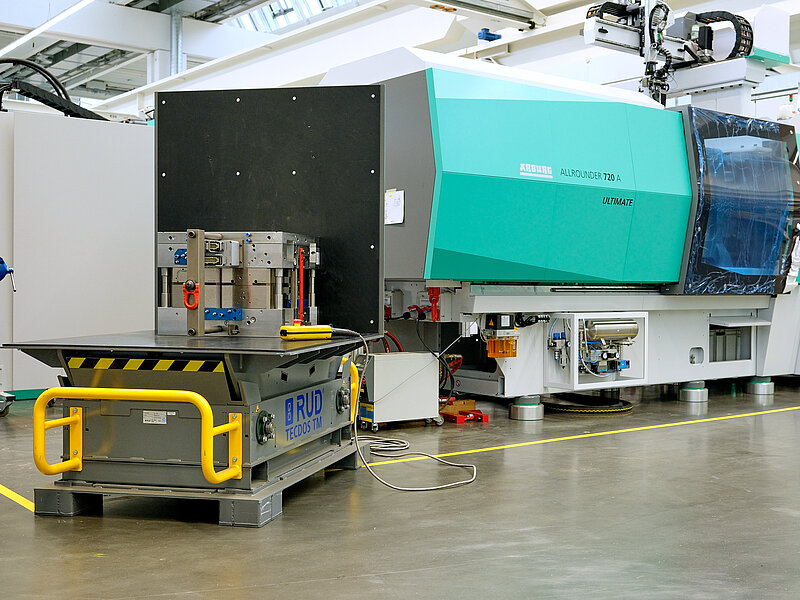

Manually opening tools weighing several tons with a sledgehammer and pry bar is a thing of the past. Tool handling is safer and, above all, faster with the new RUD TECDOS TS. This innovation from the drive specialist opens injection, punching, and forming tools in a matter of seconds, once again revolutionizing processes in production, maintenance, and repair. Thanks to optimized processes, the RUD TECDOS TS pays for itself in less than a year. Not only plant and workshop managers and controllers will be delighted, but also occupational safety officers and employees. This is because working with the new tool opener from RUD is particularly ergonomic and safe. The RUD TECDOS TS is therefore the ideal complement to the RUD TECDOS TM, the tool turner.

“The RUD Tecdos TS is a real milestone for safe and efficient tool handling,” emphasizes Anne Kühling, Product Manager in the Conveying & Drive Technology division at RUD Ketten Rieger & Dietz GmbH u. Co. KG. "The request for our new development came directly from the market. No wonder: in many companies, tools weighing several tons are opened by hand, using cranes, sledge hammers, and pry bars. Depending on the tool, this can take anywhere from half an hour to three hours and require up to three employees at the same time. Or other machines are used and ‘misused’ to open the tool, such as injection molding machines or spot welding presses. This is extremely inefficient and therefore has a significant impact on operating costs. A solution was urgently needed," Kühling continues.

Tools open in just a few seconds.

This is exactly what the RUD TECDOS TS offers. Instead of three hours and three employees, it takes a maximum of five minutes and one person for the entire process. The tool opener from RUD operates with an opening and closing force of 50 kN (equivalent to 5 tons). A PLC control system ensures intelligent operation. Controlled force and speed ensure that the tool halves open smoothly and close precisely: The force can be adjusted from a theoretical 0 kN to 55 kN, and the speed from 0 mm to 2,000 mm per minute.

Low working height for greater ergonomics.

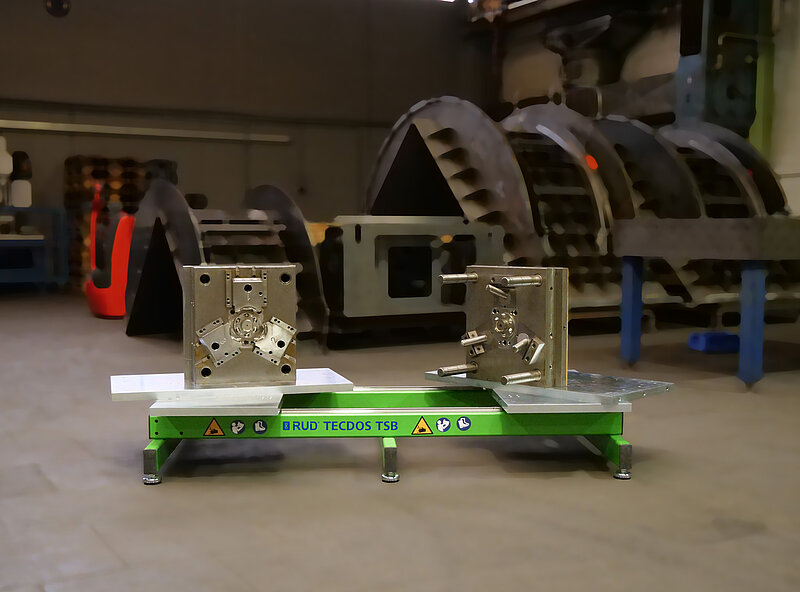

The use of the RUD TECDOS TS not only protects expensive tools, but also the joints and spines of employees. With a support surface height of only 380 mm, it is particularly ergonomic to work with. Another advantage is that after controlled opening, the employee can work directly on the two tool halves on the RUD TECDOS TS. This in turn reduces downtime due to repair work. Safety is always guaranteed. As long as a person is between the two tool halves, the tool opener cannot be operated – neither by a button on the machine nor by remote control.

Compact design thanks to electric drive.

The tool opener is electrically driven by the innovative 2-in-1 chain drive system TECDOS PI-GAMMA from RUD, which was specially developed for horizontal and vertical applications. The system is based on a high-performance round steel chain, also from RUD. The drive system is particularly force-resistant, low-maintenance, and durable.

"With its electric drive, the RUD TECDOS TS is truly unique, as we have completely dispensed with hydraulics. Not only does this require more maintenance, but it also takes up more space due to the additional hydraulic unit. The RUD Tecdos TS, on the other hand, is a compact all-in-one system,“ explains Walter Lais, design engineer at RUD Ketten Rieger & Dietz GmbH u. Co. KG. ”The compact design allows us to achieve a particularly low contact surface of 380 mm. This offers users an excellent ergonomic working height."

Up to the task of any tool.

The RUD TECDOS TS is designed as a custom-made product. The standard version of the tool opener is designed for tools weighing up to 10 tons, but lighter or heavier tools can also be accommodated without any problems. The tool opener has a 1,300 mm x 1,300 mm clamping plate and a 380 mm high sliding and support surface. “In principle, anything is possible here: we can handle smaller and larger weights, forces, and distances between the clamping plates. We can also modify the plates themselves depending on requirements,” emphasizes Lais. For flexible use in operation, the RUD Tecdos TS can be moved by crane.

In addition to the automatic stop function, which activates as soon as someone is on the RUD TECDOS TS, optional attachments such as a protective bar ensure a high level of work safety. A light curtain or protective fence are available to optimize safety in the work environment. The tool opener can be conveniently operated from outside the danger zone using radio-controlled operating devices.

The dream team for tool handling: RUD TECDOS TM and RUD TECDOS TS.

The new generation of the RUD TECDOS TM tool changer has already brought about a cool change in tool maintenance. The RUD TECDOS TS is the logical addition to this. "With the RUD TECDOS TM and the RUD TECDOS TS, we offer the ultimate dream team for process- and cost-optimized, safe, and ergonomic tool handling. And that in a wide variety of areas: from toolmaking to stamping and bending technology, aluminum die casting and injection molding to automotive, packaging, and containers,“ emphasizes Anne Kühling. ”Two separate machines also help to minimize employee waiting times, as they can work independently of each other."

Author: Sabrina Deininger