The tool turner from RUD optimizes processes.

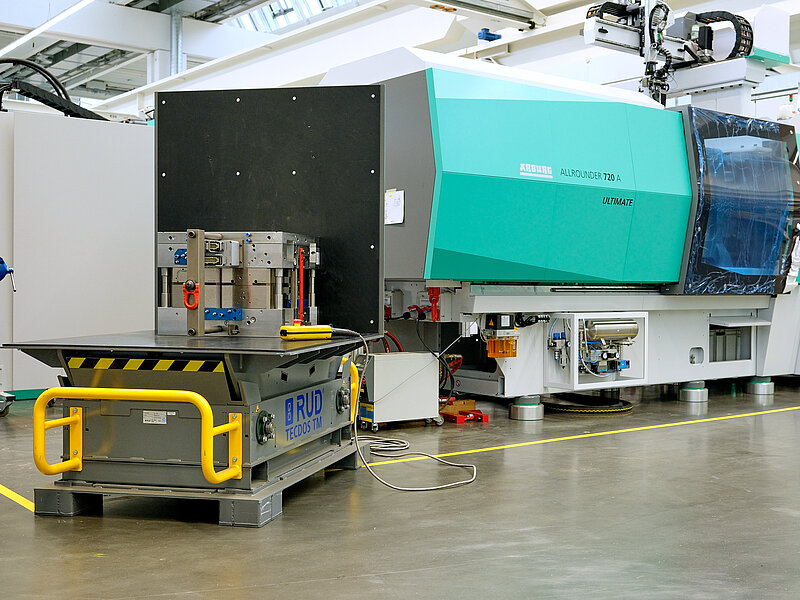

A cool move for heavy tools and molds: Where a crane and at least two employees were previously needed to remove tools weighing several tons from injection molding machines or bulky machine parts, the RUD TECDOS TM now comes into play. The innovative tool turner offers the user a significantly larger table at an extremely low working height. This is not only cool for the tool, but also for plant and workshop managers, occupational safety officers, and controllers: because handling tools with the RUD Tecdos TM is now safer, more efficient, and more budget- and process-optimized than ever before.

The RUD TECDOS TM is available in different configurations depending on requirements. The smallest slim version, for example, has a table width of only 800 mm and can carry loads of up to ten tons. The turntable is ideal for use in tool and mold making, injection and die casting, punching, bending, and forming technology, as well as in the automotive, electronics, and packaging industries.

"If you want a win-win situation for everyone involved in maintenance, there's no way around the RUD TECDOS TM. The controllers are delighted that the investment will pay for itself in less than a year. Plant and workshop managers benefit from a rapid reduction in maintenance time, and the service teams in the workshop enjoy improved ergonomics and increased safety at work without the risk of injury," explains Anne Kühling, Product Manager for Drive and Conveyor Technology at RUD Ketten Rieger & Dietz GmbH u. Co. KG, based in Aalen.

Ergonomics and occupational safety in focus.

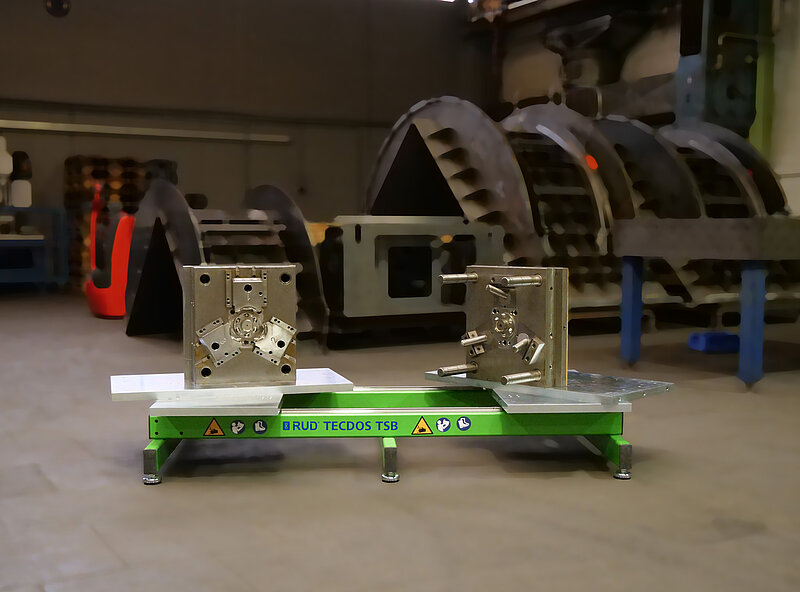

Great for users: In the new generation of turntables, RUD engineers have lowered the working surface to a height of 595 mm, even on the smallest model. "It was important to us to enable users to work in a particularly ergonomic manner. The low working height means that an open tool can be serviced directly on the table. This helps to keep employees healthy and, of course, also reduces setup costs," says Klaus Pfaffeneder, Head of the Design Department at RUD Ketten (Conveying & Drive Technology).

The RUD TECDOS TM revolutionizes maintenance processes and enables absolutely BGV-compliant, safe working. “Anyone who drags or pulls loads across the hall floor with a crane is not only working in a fire-hazardous manner, but also in violation of current standards, as §37 of the accident prevention regulations for cranes issued by the professional associations expressly prohibits this,” says Kühling.

With integrated high-end drive system.

The RUD TECDOS TM makes it really easy: The innovative tool turner is designed for axial rotary movements of tools and machine components weighing up to 64 tons, thus guaranteeing safe turning and rotating of heavy weights. The load is turned at its center of gravity and therefore extremely smoothly. The table of the RUD TECDOS TM has a frequency-controlled drive, which ensures particularly smooth starting and stopping. The tool turner is equipped with a high-end drive system from the TECDOS range.

Faster than a crane.

Compared to tool handling with a crane, turning with the RUD TECDOS TM is at least twice as fast: it takes less than a minute. Plugs or cooling hoses, which often have to be removed for safety reasons during crane maintenance, can simply remain in place during maintenance with the innovative turning table from RUD.

A revolution in planning.

Those who have a RUD TECDOS TM in their workshop may even be able to dispense with the expensive investment of a crane installation altogether, thus saving a lot of money. This is because the turning device can be moved with an industrial truck (forklift, pallet truck, etc.) and can therefore be used anywhere in the company. "This offers companies completely new possibilities in hall planning. Maintenance logistics can be completely rethought, offering entirely new potential in hall layout and, of course, for handling processes," explains Anne Kühling.

Another advantage is that the RUD TECDOS TM protects the entire infrastructure, such as the workshop floor, as the tools and machine components to be maintained no longer have to be dragged across the floor of the hall.

Wide range.

The RUD TECDOS TM is available in eight standard sizes and is suitable for a wide range of tool sizes. In the smallest version with a table top of 800 mm x 1300 mm (L x W), it can handle weights of up to 10 tons. The TM 25/35-64, the largest standard version, gently and safely moves tools and machine components weighing up to 64 tons on its 2500 mm x 3500 mm table surface (L x W).

Depending on requirements and customer specifications, RUD equips its TECDOS TM with different polyethylene table tops; slip-resistant polyurethane table tops are also available as an option. Optional attachments such as a protective bar or an intervention guard also ensure a high level of work safety. A light curtain or protective fence is available to optimize safety in the working environment. A special work platform for the secure attachment of slinging points and lashing equipment is also available as an option.

The RUD TECDOS TM control units are also particularly practical, allowing employees to operate the slewing table safely and conveniently from outside the danger zone via radio control.

Author: Sabrina Deininger