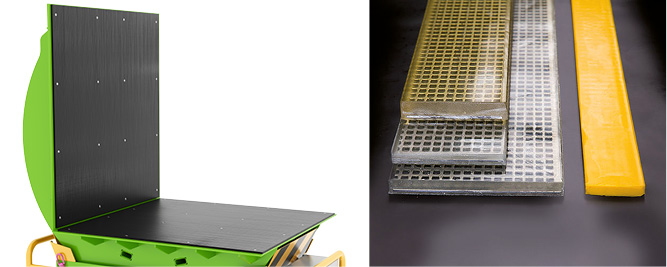

Standard plates

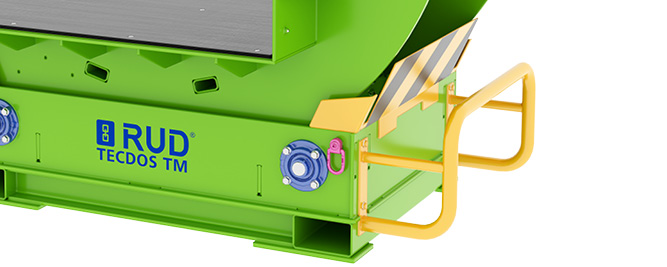

The mould flipper RUD TECDOS TM, also referred to as a "turning crossbeam", "tool mover" or "tool-handling machine", turns, rotates, and tilts moulds in a matter of seconds, at the touch of a button. The compact turning fixture does not need to be anchored to the floor. This means it can easily be moved using a forklift.

Turning injection moulds and tools has never been so safe or so efficient. The payback period for the mould flipper is less than one year. This makes the RUD TECDOS TM the most cost-effective means of avoiding damage and risks to operators.

The mould flipper RUD TECDOS TM is controlled remotely and can turn, rotate, or tilt injection moulds weighing up to 64 tonnes in a matter of seconds.

On request, you can get a bespoke plate for your RUD TECDOS TM. Choose a plate that is specifically tailored to your requirements or contact us with your enquiry.

To the RUD TECDOS TM plates.

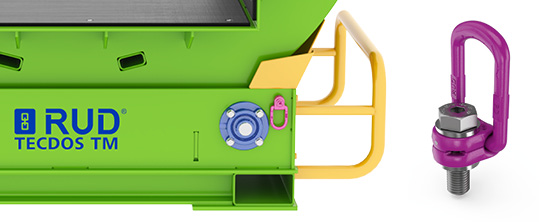

Hoop design provides distance protection:

| Type | Table surface | Table top height | Load-bearing capacity | Weight | |

|---|---|---|---|---|---|

| W (mm) | L (mm) | in mm | in kg | approx. in kg | |

| TM 08/10-5 | 800 | 1,000 | 542 | 5,000 | 600 |

| TM 08/13-10 | 800 | 1,300 | 595 | 10,000 | 1,050 |

| TM 13/13-10 | 1,300 | 1,300 | 595 | 10,000 | 1,150 |

| TM 15/18-16 | 1,500 | 1,800 | 885 | 16,000 | 3,700 |

| TM 20/20-20 | 2,000 | 2,000 | 885 | 20,000 | 4,000 |

| TM 20/25-25 | 2,000 | 2,500 | 1,167 | 25,000 | 8,000 |

| TM 25/25-32 | 2,500 | 2,500 | 1,167 | 32,000 | 8,000 |

| TM 25/25-40 | 2,500 | 2,500 | 1,167 | 40,000 | 8,000 |

| TM 25/35-64 | 2,500 | 3,500 | 2,075 | 64,000 | 17,000 |